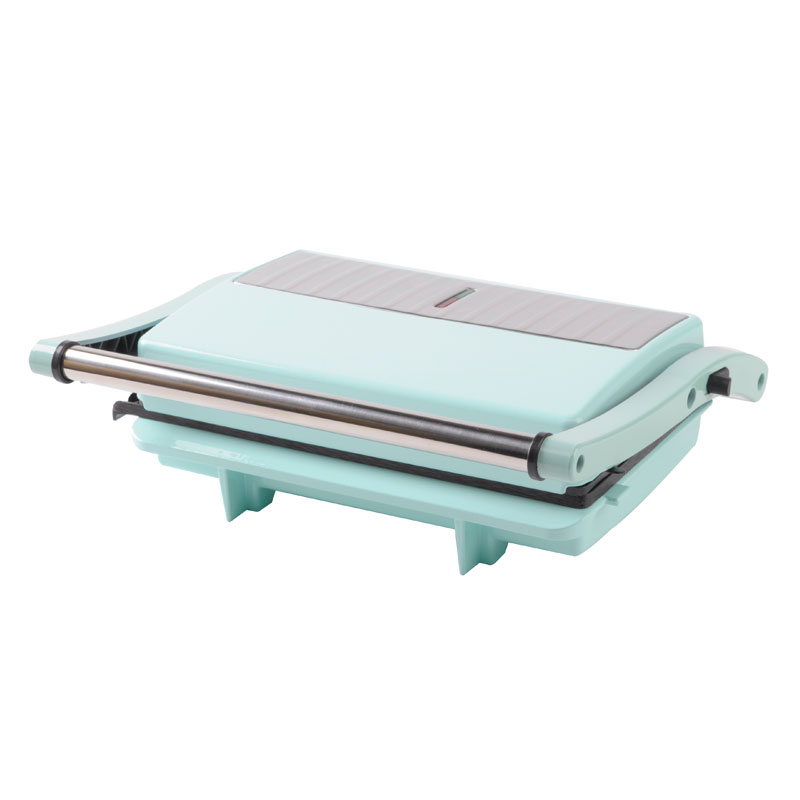

How to Clean the Non Stick Electric Panini Grill?

2025-06-20

The non stick electric panini grill is a hot-pressed cooking device with a metal matrix composite Teflon coating as its core. Its features include an integrated heating plate, a constant temperature control system, and a microporous oleophobic surface. Its cleaning is essentially a non-destructive removal process of chemical residues on the interface.

The thermal expansion coefficient of the polytetrafluoroethylene coating of the non stick electric panini grill is higher than that of the metal substrate. During the cooling process, the coating shrinks slightly to form a physical peeling force, causing most of the coked grease to fall off automatically. Residue removal must be carried out when the residual temperature is still there. High temperature will accelerate the carbonization of grease and the combination with the coating.

In addition, when cleaning this machine, be careful to avoid using acidic detergents, because this will corrode the interface layer of the aluminum oxide substrate, and alkaline substances will destroy the crystallinity of the fluorocarbon bond. Abrasive particles are embedded in the micropores of the coating to form permanent scratches, and mechanical scratching causes the surface energy to increase and lose oleophobicity.